- Overview

- Details & Specs

- Related

Screw conveyor – Vertical conveying for large-scale feed production

Contact for Price

Product Attribute

1 years

Product information

The screw conveyor is used in feed pellet processing lines to efficiently transport raw materials such as corn, soybean meal, and bran, as well as crushed powders, mixed materials, and finished pellets.

The equipment features a closed casing design to prevent dust leakage and cross-contamination of materials, meeting the hygiene standards of feed production. The specially designed blades ensure smooth and residue-free conveying, preventing damage to feed pellets or dust generation, thus guaranteeing product quality. Its compact structure and small footprint allow for flexible integration between equipment such as batching bins, crushers, mixers, pelletizers, and finished product bins, enabling continuous vertical/inclined conveying and adapting to automated production lines.

Made of wear-resistant carbon steel or food-grade stainless steel, it is durable and easy to clean, meeting the high-frequency operation requirements of feed production. Low energy consumption and convenient maintenance significantly reduce manual handling costs, ensuring continuous and efficient operation of the production line and helping feed companies achieve large-scale, standardized production.

Basic Information

- Total Capitalization: NA

- Year Established: NA

- Total Employees: NA

- Product Certificate: NA

- Business Type: Trading Company

Trading Capabilities

- Total Annual Revenue: NA

- Export Percentage: NA

- OEM Services: NA

- Small Orders Accepted: NA

- Brand Names: NA

- Payment Terms: NA

- Main Competitive Advantages: NA

- Major Customer: NA

- Export Markets: Asia , Mid East/Africa , North America

Latest Products from this Supplier

-

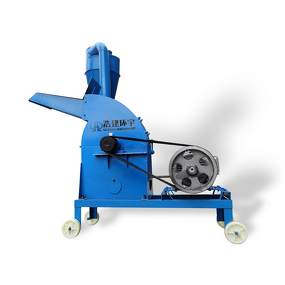

Forage Chopper: High-quality feed shredder – an efficient equipment for processing forage and straw.

Forage Chopper: High-quality feed shredder – an efficient equipment for processing forage and straw. -

High-efficiency toothed-claw crusher – equipment for processing materials such as corn stalks.

High-efficiency toothed-claw crusher – equipment for processing materials such as corn stalks. -

High-efficiency hammer mill – Specialized in crushing corn stalks, hay, and agricultural and livestock waste.

High-efficiency hammer mill – Specialized in crushing corn stalks, hay, and agricultural and livestock waste. -

Forage pulping machine – rapidly crushes and macerates alfalfa, silage corn, and ryegrass into a pulp, improving feed palatability.

Forage pulping machine – rapidly crushes and macerates alfalfa, silage corn, and ryegrass into a pulp, improving feed palatability. -

Industrial and household dual-purpose stainless steel blender – versatile for chemical and food processing.

Industrial and household dual-purpose stainless steel blender – versatile for chemical and food processing. -

Vertical feed mixer – for uniformly mixing concentrated feed and additives, improving livestock feed intake and nutrient absorption.

Vertical feed mixer – for uniformly mixing concentrated feed and additives, improving livestock feed intake and nutrient absorption. -

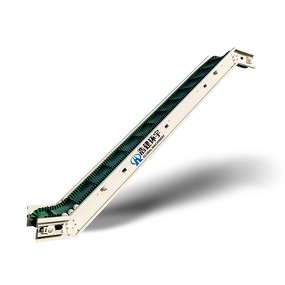

Sidewall belt conveyor – 0-90° adjustable corrugated sidewall conveyor belt

Sidewall belt conveyor – 0-90° adjustable corrugated sidewall conveyor belt -

Multifunctional Granulator – Dual-purpose for feed and organic fertilizer, ensuring uniform granulation and low breakage rate for improved utilization.

Multifunctional Granulator – Dual-purpose for feed and organic fertilizer, ensuring uniform granulation and low breakage rate for improved utilization. -

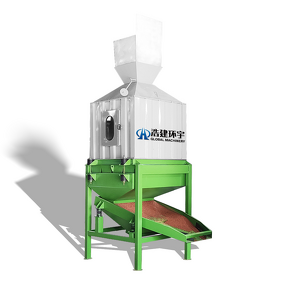

Feed processing vibrating dust collector – air cooling accelerates dust separation, preventing raw material waste and ensuring a clean workshop.

Feed processing vibrating dust collector – air cooling accelerates dust separation, preventing raw material waste and ensuring a clean workshop. -

Continuous production of feed cooling equipment ensures pellet hardness and storage stability.

Continuous production of feed cooling equipment ensures pellet hardness and storage stability.